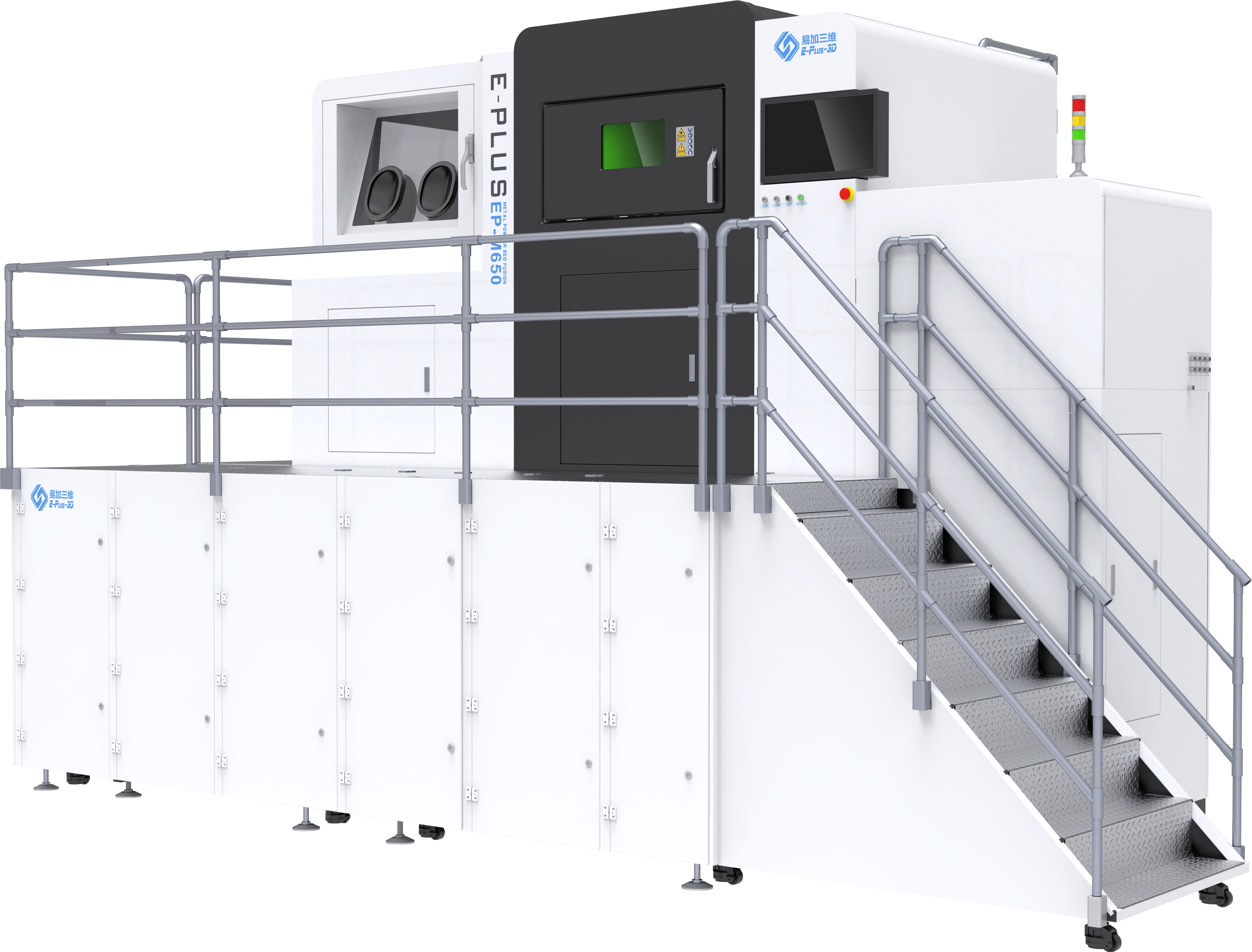

EP-M300 Metal 3D Printer Features

-

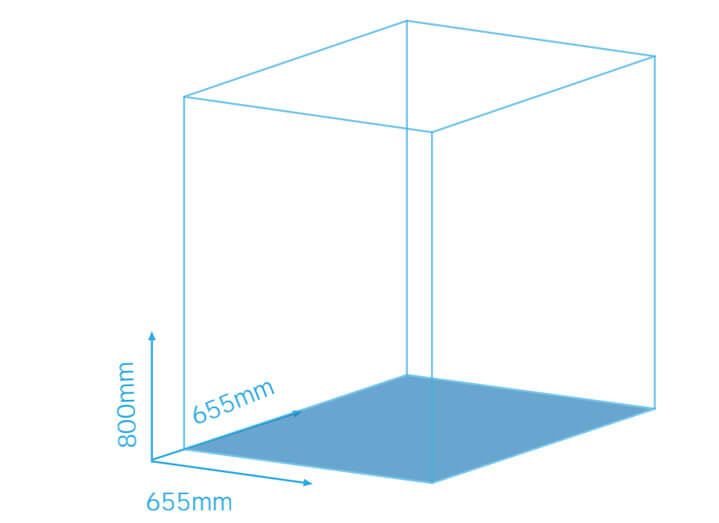

Printing of mass-individualized parts in the 340 Liter (655 x 655 x 800 mm³) build chamber.

-

Four lasers are printing simultaneously with up to 120 cm³, which is increased efficiency by 3.5 times compared to a single laser system.

-

Printing large layer thicknesses of more than 60 um are possible.

-

High parts accuracy in the overlap area of 0.1 mm. The deviation of mechanical properties compared to a single laser system is lower than 3%.

-

Optimized design the air flow ensures the effective removal of dust and splatter as well as a unifrom parts quality in the whole print bed.

-

The strict calibration ensures the consistency between parts and batches.

-

Friendly user interface with fully automatic one-click printing function.

-

The build job information is displayed in real time with traceable printing parameters and a detailed printing report.

-

The one-piece take out function ensures a high automation and low downtime, due to an automatic movement of the building cylinder into the cleaning module after the print is finished.

-

Safety design, prevent misoperation, electric shock, fire, waste and pollution.

-

Outstanding overall sealing performance, use and recovery of powder in a closed state.

-

Environment and gas source state Real-Time Monitoring, safe and reliable.

-

We support our customers with technical consulting services, including data evaluation, and application development.

-

Assisting our customers in new material parameter development. Existing parameter packages are provided free of charge.

-

Free equipment installation and maintenance during the warranty period, full set of technical training is provided.

Technical Specifications

| Machine Model | EP-M650 |

| Build Volume (XxYxZ) | 655x655x800mm³ |

| Optical System | Fiber Laser4*500W |

| Spot Size | 80-120µm |

| Max Scan Speed | 8m/s |

| Layer Thickness | 20-120µm |

| Building Speed | 120cm³/h |

| Material | Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

| Substrate heating | Substrate heating temperature 200℃ |

| Power Supply | 380V, 64A, 23kW, 50 / 60Hz |

| Gas Supply | Ar/N₂ |

| Forming chamber oxygen content | ≤100ppm |

| Dimension (WxDxH) | 6800*3945*3785mm³ |

| Weight | 15000kg |

| Software | EP-Hatch, EP Control |

| Input Data Format | STL file or another convertible format |

Download Brochures: Link